Basics of UHF RFID Technology

A Comprehensive Overview of UHF RFID Technology

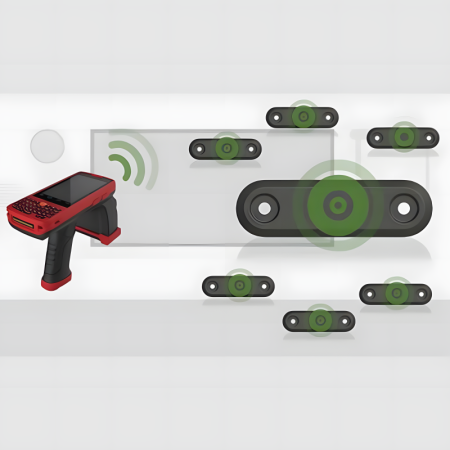

UHF RFID technology, which stands for Ultra High Frequency Radio Frequency Identification technology, operates within the frequency range of 860MHz-960MHz and boasts an impressive bandwidth of 100MHz. By harnessing the power of backscattering principle and employing an efficient anti-collision algorithm, UHF RFID readers excel in delivering a high transmission rate and the ability to rapidly read a vast number of electronic labels. Consequently, UHF RFID technology proves to be an excellent choice for large-scale business applications, offering substantial advantages in terms of enhancing supply chain management efficiency and bolstering anti-counterfeiting traceability.

The applications of UHF RFID technology are diverse and far-reaching. It finds extensive use in inventory and supply chain management, enabling businesses to streamline their operations and optimize their logistics processes. Moreover, UHF RFID is a valuable asset in the realm of smart manufacturing, contributing to the automation and optimization of production lines. It also plays a crucial role in airline baggage tracking, ensuring that luggage is accurately traced and accounted for throughout its journey. Additionally, UHF RFID technology is instrumental in sports timing, facilitating precise measurements and recording of athletes’ performance.

Within the designated frequency range, regulatory agencies have established specific sub-bands for different regions. For instance, the European Telecommunications Standards Institute (ETSI) has defined the frequency range of 865 – 868 MHz for RFID use in Europe, while the US Federal Communications Commission (FCC) has selected the range of 902 – 928 MHz for RFID use in the United States. To cater to these regional variations, our range of RFID tags and inlays are designed to be compatible with either FCC or ETSI frequencies. Furthermore, many of our newer products are engineered to support both frequency bands, ensuring maximum flexibility and compatibility.

When compared to HF (High Frequency) and LF (Low Frequency), UHF systems offer distinct advantages. The most notable advantage is the longer read range, enabling RFID readers to capture data from a greater distance.

Frequency

Distribution of RFID frequency bands worldwide

Based on the commonly used UHF RFID frequency bands worldwide, Japan has the highest frequency band, ranging from 952-954MHz. The majority of UHF frequency bands for wireless communication transmission are concentrated between 902-928MHz.

Countries and regions | Frequency | Power |

China | 840 ~ 845MHz | 2W ERP |

920 ~ 925MHz | 2W ERP | |

Singapore | 866 ~ 869MHz | 0.5W ERP |

923 ~ 925MHz | 2W ERP | |

Hong Kong | 865 ~ 868MHz | 2W ERP |

920 ~ 925MHz | 4W EIRP | |

South Africa | 917 ~ 921MHz | |

865.6 ~ 867.6MHz | ||

Vietnam | 920 ~ 923MHz | |

866 ~ 869MHz | ||

Brazil | 902 ~ 907.5MHz | |

915 ~ 928MHz | ||

United States | 902 ~ 928MHz | |

Canada | 902 ~ 928MHz | |

Mexico | 902 ~ 928MHz | |

Turkey | 865.6 ~ 867.6MHz | |

Israel | 915 ~ 917MHz | |

Iran | 865 ~ 868MHz | |

Thailand | 920 ~ 925MHz | |

Malaysia | 919 ~ 923MHz | |

South America | 902 ~ 928MHz | |

North America | 902 ~ 928MHz | 4W EIRP |

Europe | 865 ~ 868MHz | 2W ERP |

Japan | 952 ~ 954MHz | 4W EIRP |

South Korea | 910 ~ 914MHz | 4W EIRP |

Australia | 918 ~ 926MHz | 4W EIRP |

New Zealand | 864 ~ 868MHz | 4W EIRP |

India | 865 ~ 867MHz | 4W ERP |

Taiwan | 922 ~ 928MHz | 1W ERP |

Protocol ISO18000-6C

RFID ultra-high frequency (UHF) is an international standard for RFID radio frequency identification applications. It is referred to as UHF high frequency ISO18000-6C (EPC CLASS1 G2) protocol standard. This standard defines electronic tags that operate at a frequency range of 860MHz to 960MHz with a bandwidth of 100MHz. UHF readers mostly use frequency hopping transmission methods, allowing the same tag to be read by the corresponding protocol anywhere in the world without being affected by radio frequency bands in different areas. The tags are anti-collision, can be deployed in various environments globally, have read/write field programmability, faster tag read/write speeds, and can operate in reader-dense environments.

The ISO18000-6C (EPC CLASS1 G2) tag logically divides its memory into four storage areas, each composed of one or more memory words.

Reserved area (Password)

The first two characters represent the kill password, and the last two characters represent the access password. This area is readable and writable.

EPC area (EPC)

It consists of three parts: CRC-16, protocol control bit (PC value), and EPC data. The EPC data can be read and written.

TID area (TID)

It stores the ID number set by the tag manufacturer. Currently, there are two types of ID numbers: 4-character and 8-character. This area is readable but not writable.

User area (User)

This area varies for different manufacturers. For example, Impinj's G2 tags do not have a user area, while Philips company has 28 words in their user area. Currently, NXP's U Code DNA has a maximum capacity of 3K, which can be read and written.

All four memory areas can be write-protected, which means they can never be written or cannot be written in a non-safe state. Additionally, read protection can be set for the password area, restricting its read access.

RFID ICs

Tag chips used for UHF (Ultra High Frequency) are primarily produced by NXP, Alien, and Impinj, which are the dominant players in the UHF general-purpose chip market. These manufacturers have established a significant presence in the field of general-purpose chips, driving other UHF tag chip players to focus more on customized development for specific application fields.

In addition to NXP, Alien, and Impinj, there are also other notable players in the UHF tag chip market. For instance, Yuanwanggu, Beijing Zhixin Micro, Shanghai Kunrui, Yuehe Technology, and Kailuwei are actively involved in the development and production of UHF tag chips for various specialized applications.

RFID Antenna / Inlay

UHF Inlays are primarily produced using three technologies: the hot stamping method, the conductive ink printing method, and the printing method.

Hot stamping method

Conductive ink printing method

Another popular method for UHF inlay production is the conductive ink printing method. This technique involves the use of specially formulated conductive inks that contain metal particles, allowing for the printing of antennas and circuits directly onto various materials. Conductive ink printing offers flexibility in terms of design and customization, as it allows for the creation of intricate antenna patterns on a wide range of substrates. This method is particularly suitable for applications where space is limited or unconventional shapes are required.

Printing method

The printing method is a widely used and efficient approach for UHF inlay production. By utilizing advanced printing technologies, antennas and circuits can be produced with precision and accuracy. This method offers scalability and cost-effectiveness, making it suitable for high-volume production. With continuous advancements in printing technology, the printing method continues to evolve, enabling the creation of smaller and more intricate antenna designs.