Frequently Asked Questions

MAKARFID FAQ

Explore our comprehensive FQA page for RFID products, where we address frequently asked questions, providing valuable insights and clarity to help you make informed decisions for your RFID needs

RFID Technology Basic Knowledge

MAKARFID FAQ

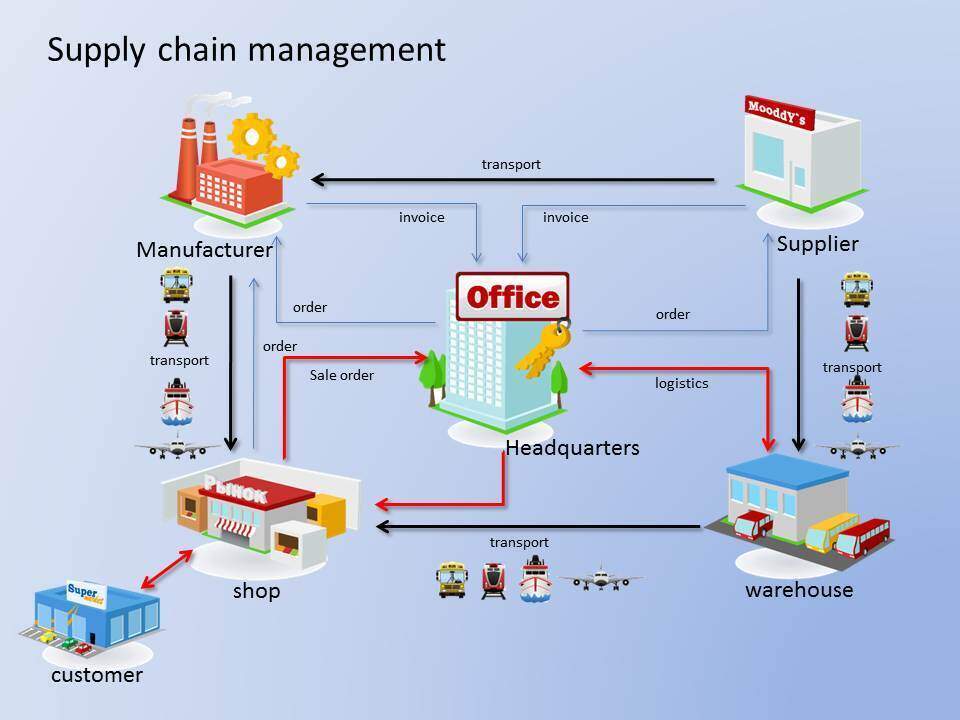

An RFID system includes tags or labels attached to the items being identified, readers that interact with the tags, and a database that stores and manages the information. This technology is widely used in numerous industries for inventory management, access control, supply chain tracking, and any other applications requiring object or individual identification and tracking.

RFID (Radio Frequency Identification) uses electromagnetic fields to identify and track tags on objects. It works as follows:

- RFID Tag: This has a microchip storing data and an antenna for communication. Tags can be passive (no power source) or active (with power source).

- RFID Reader: Emits radio waves, communicates with tags, and retrieves their stored data.

- Communication: When a tag enters the reader’s electromagnetic field, it powers up, modulates the signal with its data, and sends it back.

- Data Retrieval: The reader captures the tag’s signal, decodes the data, and transfers it to a computer for further action.

- Applications: RFID is used in various industries for tasks like inventory tracking, supply chain monitoring, product identification, access control, and more.

RFID provides wireless object tracking, streamlining operations and enhancing efficiency.

Radio Frequency Identification (RFID) technology has been around for a while and has a multitude of uses across various industries. From tracking inventory in warehouses to enhancing security measures, RFID is a game-changer in the tech world.

RFID is primarily used for identification and tracking purposes. In retail, for instance, it can be used to track inventory and reduce theft. In logistics and supply chain management, RFID tags attached to packages can help companies track their goods throughout the delivery process, improving efficiency and accuracy.

RFID is also used in access control systems, such as key cards for secure buildings or badges for employees. By simply swiping the card or badge, the system can verify whether the person has access rights.

In healthcare, RFID technology is used to track medical equipment and even patients. This helps to reduce errors, improve patient safety, and increase efficiency in hospitals.

Moreover, RFID is used in agriculture to track livestock, helping farmers to manage their herds more effectively. It can also be used to track wildlife for research purposes.

These are just a few examples of how RFID technology is used. As technology continues to advance, we can expect to see even more innovative uses for RFID in the future.The maximum read distance of RFID (Radio Frequency Identification) systems can vary based on several factors. These include the frequency used, the power of the RFID reader, the type of RFID tags, and the environment where the system is deployed.

Generally, RFID systems’ read distances can range from a few centimeters to several meters. Here are common RFID frequencies and their typical read distances:

– Low-frequency (LF) RFID systems (125-134 kHz): Read distances usually range from 8 centimeters to around 80 centimeters,the greater the power of the reader, the farther the reading distance is.

– High-frequency (HF) RFID systems (13.56 MHz): Read distances can vary from 3 centimeters to roughly 1 meter. The larger the power of the card reader, the further the reading distance. At the same time, the larger the tag, the further the reading distance, and the higher the sensitivity. The reading distance using a mobile phone is usually only 3-5 centimeters, and the reading distance of the ISO15693 protocol is longer than the reading distance of the ISO14443 protocol.

– Ultra-high-frequency (UHF) RFID systems (860-960 MHz): Read distances can span from 1 meter to over 15 meters. The reading performance of tags is affected by many factors, including the metal properties of the working environment, and interference from liquids and the human body. These factors may shorten the reading distance. The distance to read a single tag is further than reading multiple tags at the same time. Using tags in an environment with more metal, the reading distance may also be weakened.

Remember, to achieve the maximum read distance, you may need to optimize the RFID system setup. This includes the placement of antennas, the RFID reader’s power output, and the selection of suitable RFID tags.

RFID technology varies based on the frequency or “wave” it operates on. The maximum distance it can achieve depends on numerous factors:

- The operating frequency of the RFID system, or bandwidth if it involves multiple frequencies

- The RFID reader and its particular settings

- Characteristics of the antenna, such as type, gain (dBi), center frequency, VSWR, polarization, size, and IP rating

- Characteristics of the RFID tag, like its size, shape, polarization, and tuning

- Thickness and material of the object to which the tag is attached

- Material of the object that the RFID tag is attached to

- Tag orientation relative to the reading antenna

- Method used to attach the tag, which could be adhesive, tape, staple, rivet, screw, cable tie, magnetic, embedded, and more

- Environment where the RFID solution is being utilized

In addition, there are several other factors that could influence the functionality.

RFID Frequency Define

MAKARFID FAQ

RFID systems, or Radio-Frequency Identification systems, function at a variety of frequencies. Each frequency has different effects on the system’s performance and characteristics. The common frequency bands utilized in RFID systems are:

Low-Frequency (LF) RFID: These systems operate within the frequency range of 125-134 kHz. LF RFID systems possess relatively shorter read ranges that typically extend up to 1 meter. However, they demonstrate greater resistance to interference from metallic substances and liquids. Due to these characteristics, LF RFID systems are commonly employed in scenarios requiring access control, animal tracking, and proximity applications.

High-Frequency (HF) RFID: HF RFID systems function at a frequency of 13.56 MHz. They offer read ranges that can reach up to 1 meter. The practical applications of HF RFID systems are diverse, encompassing payment systems, ticketing services, and the tracking of library books. Near Field Communication (NFC) is a short-range wireless communication technology, operates at 13.56 MHz frequency, which is in the High-Frequency (HF) range.

Ultra-High-Frequency (UHF) RFID: UHF RFID systems operate within the frequency range of 860-960 MHz. These systems provide significantly longer read ranges, extending up to several meters. This makes them particularly suitable for applications such as inventory management, supply chain tracking, and retail operations.

The selection of RFID frequency is influenced by a combination of factors. These include the required read range, environmental conditions, considerations of interference, and regulatory requirements. Each frequency band comes with its unique set of advantages and limitations. Therefore, the selection of the appropriate frequency is a crucial aspect of successfully implementing an RFID system.

ISO 14443A is a standard for smart cards and proximity cards that function at 13.56 MHz. It establishes the methods of communication and data transmission between the card and the reader. MIFARE, a contactless smart card technology developed by NXP Semiconductors, is one of the most notable implementations of the ISO 14443A standard.

The ISO 14443 standard is an integral part of the Near Field Communication (NFC) standard. This standard plays a crucial role in facilitating the integration of emerging technologies into existing systems. A prime example of this is the use of smartphones for identification purposes. The beauty of the ISO 14443 standard is that it allows for this integration without the need for incurring high retrofit costs.

NXP, a leading technology company, offers four distinct families of MIFARE products. Each of these product families has been meticulously designed to meet specific needs and requirements. The range of products ensures that various sectors and industries can find an appropriate solution that aligns with their unique needs.

MIFARE Classic

The MIFARE Classic is a highly versatile solution that supports systems that are not heavily focused on security. It is also a perfect choice for maintaining compatibility with legacy systems. This makes it suitable for a wide range of applications where basic security requirements are sufficient.

MIFARE Plus

MIFARE Plus integrates advanced AES security, offering a level of protection that far exceeds that of the MIFARE Classic. It allows for smooth and seamless upgrades from MIFARE Classic, making it an ideal choice for systems looking to enhance their security without significant infrastructure changes.

MIFARE Ultralite

MIFARE Ultralite is a cost-effective solution for applications that require a high volume of cards but want to keep costs low. It provides the perfect balance between affordability and functionality, making it a popular choice for large-scale deployments.

MIFARE DESFire

The MIFARE DESFire, available in both EV1 and EV2 versions, provides top-notch security for critical applications. With DESFire, you can rest assured that your system’s security is optimized to the highest level, making it a preferred choice for applications where security cannot be compromised.

High Frequency 13.56 MHz RFID technology, based on ISO 15693 and ISO 18000-3 standards, provides longer read ranges, an effective anti-collision mechanism, and dependable communication. This is beneficial for various RFID applications across different industries.

NXP ICODE RFID Chip: The NXP ICODE is a well-known RFID chip that complies with the ISO 15693 standard for high-frequency (13.56 MHz) RFID technology.

Features:

MIFARE Security Features: The NXP ICODE chip includes certain security features commonly found in MIFARE technology, enhancing the overall security of the chip.

User Memory: The chip can store EPC codes or other data in its user memory, providing flexibility for storing various types of information.

Development Purpose:

Counterfeiting Issues: The NXP ICODE chip was developed by NXP to address worldwide counterfeiting issues in sectors such as luxury footwear, accessories, pharmaceuticals, and consumer electronics.

Range Bridging: It bridges the gap between the restricted range of MIFARE or NFC technology and the extensive range of EPC (Electronic Product Code), offering automation opportunities in production lines.

Applications:

The NXP ICODE chip is used in various industries to combat counterfeiting, enhance security, and enable automation in production processes.

Benefits:

Security: By incorporating MIFARE security features, the chip provides enhanced security to prevent counterfeiting and unauthorized access to data.

Versatility: The chip’s ability to store EPC codes and other data in user memory makes it suitable for a wide range of applications in different sectors.

Industry Impact:

The NXP ICODE chip has had a significant impact on sectors facing counterfeiting challenges, offering a reliable and secure RFID solution to combat such issues.

Overall, the NXP ICODE RFID chip plays a crucial role in addressing counterfeiting concerns, enhancing security, and enabling automation in industries where authenticity and traceability are paramount.

NFC technology has revolutionized the way we make payments, interact with advertising content, and share information between devices. Its convenience, security features, and versatility have made it a key enabler for various applications in the mobile and contactless payment ecosystem.

NFC in Payment Processing:

- NFC technology has become a significant force in the payment processing industry due to its integration in modern mobile devices.

- Leading payment systems like Apple Pay, Google Pay, and Samsung Pay rely on NFC technology to enable secure and convenient contactless transactions.

- Mobile devices with NFC chips are equipped with robust security measures to ensure the safety of transactions and prevent misuse.

NFC in Advertising:

- The widespread availability of NFC readers has expanded the application of NFC technology into advertising campaigns.

- NFC tags, similar to QR codes, are now embedded in physical items such as posters, event tickets, and everyday objects to facilitate easy access to digital content.

- Scanning NFC tags allows users to download various digital content like photos, contact information, maps, and more.

Operating Modes of NFC:

Emulation Mode: In this mode, a mobile device can emulate the functionalities of an NFC tag, allowing it to mimic tag behavior.

Reader/Writer Mode: This mode enables an NFC-enabled device to request information from another NFC device or tag, facilitating data exchange.

Peer-to-Peer Mode: NFC devices can communicate with each other in peer-to-peer mode, enabling information sharing and device pairing without the need for a separate network connection.

UHF RFID, EPC Gen2, and ISO 18000-6C are all related to RFID (Radio Frequency Identification) technology, specifically in the UHF (Ultra High Frequency) range.

UHF RFID:

UHF RFID stands for Ultra High Frequency Radio Frequency Identification.

It operates in the frequency range of 860 MHz to 960 MHz.

UHF RFID technology is known for its longer read range compared to other RFID frequencies like LF (Low Frequency) and HF (High Frequency).

UHF RFID tags are commonly used for supply chain management, inventory tracking, and asset tracking applications.

EPC Gen2:

EPC Gen2 (Electronic Product Code Generation 2) is a standard for UHF RFID systems.

It is developed by EPCglobal, a standard-setting organization for RFID technology.

EPC Gen2 standardizes the communication protocol and data structure for UHF RFID systems.

EPC Gen2 tags are commonly used in retail, logistics, and healthcare industries for item-level tracking and inventory management.

ISO 18000-6C:

ISO 18000-6C is an international standard for UHF RFID air interface protocols.

It specifies the requirements for communication between UHF RFID readers and tags.

ISO 18000-6C is part of the ISO 18000 series of standards that cover various RFID frequencies and technologies.

Compliance with ISO 18000-6C ensures interoperability between different UHF RFID systems from different manufacturers.

In summary, UHF RFID is the general technology that operates in the UHF frequency range, EPC Gen2 is a specific standard for UHF RFID systems, and ISO 18000-6C is an international standard for UHF RFID air interface protocols.

EPC Gen2 (Electronic Product Code Generation 2) is a standard for UHF (Ultra High Frequency) RFID systems. It has been developed by EPCglobal, an organization that sets global standards for RFID technology. EPC Gen2 aims to provide a universal framework for RFID communication and data exchange within UHF RFID systems.

This standard defines the structure of Electronic Product Codes (EPCs) and other data elements stored on RFID tags. This standardization allows for consistent data encoding and decoding across supply chains and other applications.

EPCglobal is a trade organization leading the development of global industry standards and the implementation of EPC Gen 2 UHF RFID for modern, information-intensive trading networks. EPCglobal has branches in every country working towards establishing EPC as the standard for end-to-end supply chains.

EPC Gen 2 UHF RFID, also known as Electronic Product Code Generation 2 Ultra High Frequency Radio Frequency Identification, uses radio waves to facilitate communication between an RFID reader and a tag.

The process begins with the reader transmitting a signal specifically designed to interact with the tag. Upon receiving this signal, the uniquely programmed tag, which contains specific identification information, responds to the reader.

This almost instantaneous exchange of information makes EPC Gen 2 UHF RFID a highly efficient system for tracking and identification.

Industries such as retail, logistics, healthcare, and manufacturing commonly use EPC Gen2 UHF RFID tags for item-level tracking, inventory management, supply chain visibility, and asset tracking.

NFC AND RFID Transponder

MAKARFID FAQ

RFID, or Radio Frequency Identification, is a technology that uses radio waves for automatic identification and tracking of objects or people.

NFC AND RFID Transponder

MAKARFID FAQ

Low Frequency Bands 125Khz to134.2Khz

MAKARFID FAQ

The frequency range of Low Frequency (LF) RFID is from 30kHz~300kHz, with common frequencies including 125Khz and 134.2Khz, and its wavelength is approximately 2500m. The electronic tags in this frequency range are usually passive, powered and transmitting data through inductive coupling. These tags are passive tags, working on the principle of electromagnetic coupling, and can penetrate any object for identification except for metal, with stable recognition distance, clear induction range, and only one tag can be read at a time.

Its advantages include mature technology, low cost of reading and writing equipment, good signal penetration, unless affected by metallic materials, it can penetrate any material object without reducing the reading distance, and it is less affected by the environment.

However, its disadvantages are short reading distance, slow data transmission, and small information storage capacity.

Despite the maturity and low cost of LF systems, due to their low resonance frequency, the tags need to be made with large inductance windings, and often need to package external resonant capacitors, so the cost of their tags is higher than other frequency bands.

Low Frequency RFID is widely used, such as in access control systems, animal identification, intelligent manufacturing (such as: AGV station identification), and other aspects.

Low-frequency tags are typically passive tags, which obtain their working energy from the radiation near-field of the reader’s coupling coil through inductive coupling. When transmitting data, low-frequency tags need to be within the near-field region of the reader’s antenna radiation. Typically, the reading distance of low-frequency tags is less than 1 meter.

Typical applications of low-frequency tags include animal identification, container identification, tool identification, electronic lock anti-theft (such as car keys with built-in responders), etc. International standards related to low-frequency tags include ISO11784/11785 (for animal identification) and ISO18000-2 (125-135 kHz). Low-frequency tags come in various forms, and the forms of low-frequency tags for animal identification include collar-type, ear tag-type, injection-type, and pill-type. Typical application objects include cows, homing pigeons, etc.

The biggest advantage of low-frequency is that its tags are less affected when close to metal or liquid items, and the low-frequency system is very mature, with low-cost read-write equipment. However, its disadvantages are short reading distance, inability to perform multi-tag reading (anti-collision), and low information content, with the general storage capacity ranging from 128 bits to 512 bits. It is mainly used in access control systems, animal chips, car anti-theft devices, and toys, etc.

- a) ISO 11784: for RFID livestock applications, defining the coding structure to ensure effective transmission and identification of information.

- b) ISO 11785: for RFID livestock applications, deals with technical theory and provides basic theoretical guidance.

- c) ISO 14223-1: for RFID livestock applications, focusing on the definition and implementation of the air interface.

- d) ISO 14223-2: for RFID livestock applications, defining the protocol to ensure normal communication between devices.

- e) ISO 18000-2: this standard defines the physical layer, anti-collision and communication protocols for low frequency, providing a complete solution for low-frequency devices.

- f) DIN 30745: for European waste management applications, providing a complete waste management solution.

- Card Type Identity Recognition Market

The card type identity recognition market refers to the application fields of access control cards, key fobs, car keys, etc. Card type identity recognition is still the main application area of low-frequency RFID, as it has accumulated a large base of users over the past few decades. Besides the common access control cards, low-frequency RFID is also very common in other similar scenarios (such as swimming pool management, amusement park management, etc.).

- Animal Tag Market

The animal tag market refers to the application of low-frequency RFID based on animal management, including product categories such as animal foot rings, ear tags, and glass tube labels. There are also dog chips, which are glass tubes containing low-frequency RFID chips injected into pet dogs by pet owners when they register dog tags. Low-frequency RFID, as the best pet management method at present, will usher in new growth points.

- Industrial Applications

Industrial applications are a major application field of low-frequency RFID, among which AGV carts are a typical application scenario. Another typical industrial application scenario is workstation labels in factory workshops, as well as factory inspections and identity authentication. Due to the need for stable and reliable products in the factory environment, and the possibility of interference such as metal and shielding in some factory environments, low-frequency RFID occupies an important market position in this field.

- Special Application Market

The special application market refers to those niche markets or industries with high thresholds, which few companies can venture into. With its unique technical characteristics and project-based business model, low-frequency RFID has found a place in such special markets. At present, the most important special market for low-frequency RFID is the buried label market. In cities, due to frequent construction, if the location of underground pipelines cannot be accurately grasped, it is easy to cause damage to underground pipelines during the construction process. Water, electricity, internet, and gas are all necessities of life, and once damaged, they will have a noticeable impact. Against this background, some areas have begun to use buried labels based on low-frequency RFID to manage underground pipelines. In addition, the wafer production factories in the semiconductor industry are also one of the suitable scenarios for low-frequency RFID, because the wafer production environment has higher electromagnetic requirements, and the electromagnetic interference of low-frequency RFID is smaller, so it is more suitable.

Benefits of using RFID

Enhanced Operational Efficiency

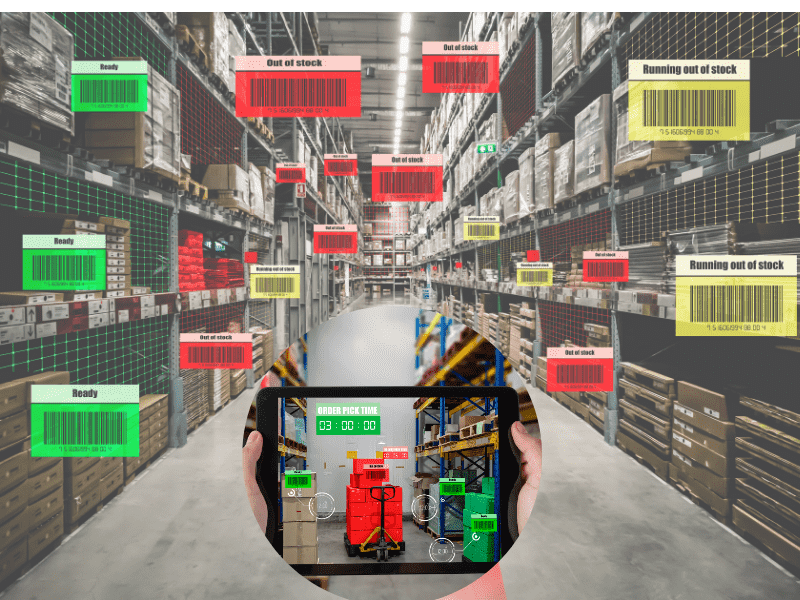

RFID solutions streamline your operations by automating data capture and management processes. With real-time tracking and accurate identification, you'll experience reduced manual data entry errors and improved inventory accuracy. This efficiency boost leads to faster workflows, optimized resource utilization, and better decision-making

Improved Asset Visibility

Gain complete visibility into your assets' whereabouts and usage with RFID technology. Whether it's equipment, inventory, or personnel, our solutions enable you to track and monitor assets seamlessly. This visibility minimizes losses, prevents theft, and ensures assets are in the right place at the right time, contributing to smoother operations and cost savings.

Enhanced Customer Experience

By utilizing RFID solutions, you elevate your customer experience. Shorter checkout times, improved inventory availability, and personalized service become achievable goals. RFID's swift and accurate data capture ensures shelves are stocked, orders are accurate, and customer interactions are smooth, leading to increased satisfaction and loyalty.

Discover Seamless Precision with MAKA RFID

We give you full support

we specialize in delivering seamless connectivity and precision through our cutting-edge RFID technology. Our range of RFID tags, labels, and readers is designed to enhance efficiency, accuracy, and visibility across various industries. Whether you’re looking to optimize inventory management, improve asset tracking, or enhance customer experiences, our RFID solutions offer the reliability and performance you need. Explore the future of seamless precision today