Integration of Drone and RFID Warehouse Systems

Logistics Innovation in the Digital Wave

Today, with the rapid development of e-commerce and the continuous increase in product categories and quantities, warehouse management faces increasingly complex challenges. Under traditional manual inventory counting methods, high labor input and efficiency fail to meet the business demands for high turnover and accuracy, with errors and omissions being commonplace. The industry urgently needs an efficient, low-cost, and automated inventory counting solution.

Technical Principles Analysis

1. RFID Technology Principles

RFID (Radio Frequency Identification) is a wireless communication technology that enables contactless automatic identification of items. Each item, box, or pallet is equipped with a unique RFID tag, and readers can simultaneously read multiple tags from a distance without needing to “aim” at or scan tags individually, greatly improving data collection speed and accuracy.

Advantages:

- No contact or line of sight required

- Batch reading capability

- Can integrate temperature and humidity sensors

2. Drone Autonomous Navigation and Data Collection

Modern warehouse drones feature high-precision positioning (such as SLAM, visual navigation, etc.) and obstacle avoidance capabilities. They can fly autonomously along predetermined routes, carrying RFID readers to achieve seamless coverage of high places, blind spots, and deep stack areas that are difficult for humans to reach, collecting real-time inventory status data and uploading it to the management system.

Typical Process: Task assignment → Autonomous flight → AI obstacle avoidance → RFID batch reading → Real-time data transmission

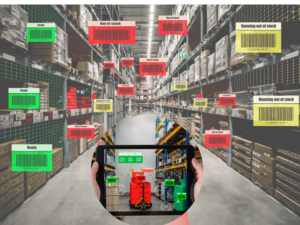

3. Digital Twin and Visual Management

The collected RFID data interfaces with the Warehouse Management System (WMS) to create a “digital twin” of warehouse space and inventory status. Inventory conditions are visualized globally and dynamically, with immediate alerts for anomalies (such as missing or misplaced items).

Drone and RFID Smart Inventory System Integration Innovation: Leading a New Era in Intelligent Warehouse Management

In the context of accelerating intelligent transformation in global supply chain management, innovative technologies are pushing the boundaries of traditional warehousing and logistics. The deep integration of drone and RFID technologies is leading inventory management into a new era.

Traditional warehouse inventory systems primarily rely on manual scanning and visual identification. While this approach has been widely used and effective in the industry, limitations such as visual obstruction and densely packed items create bottlenecks in inventory efficiency and accuracy. The introduction of RFID (Radio Frequency Identification) technology has fundamentally changed this situation. Using RFID tags, warehouse management personnel can quickly and accurately locate and identify every item in storage without direct observation, significantly improving inventory data accuracy and real-time capabilities.

More excitingly, the combination of RFID technology and autonomous drones has not only achieved automated inventory processes but also brought an unprecedented “panoramic view” to warehouse operations. Drones can fly autonomously within warehouses, working with RFID readers to navigate between shelves and scan each tagged item, effectively solving the challenges of blind spots and high-shelf inventory, making digital twin warehouse operations a reality. This innovation isn’t just a technological upgrade; more importantly, it’s reshaping the warehouse management model: freeing operational staff from tedious inventory tasks to focus on more strategic responsibilities and continuous optimization.

Case Analysis: Maersk-VERITY-On Trilateral Cooperation

Pilot Project Summary:

- Location: Maersk’s 20,000-square-meter warehouse in California, USA

- Participating Companies: Drone technology provider Verity, premium footwear and apparel brand On, global logistics giant Maersk

- Pilot Duration: 3 months

- Operational Results: 1500+ autonomous flights, 80 million RFID reads, processing 1.25 million unique tags

Business Value Achieved:

- Significant Reduction in Labor Cost and Time: Traditional team inventory takes days, drone+RFID reduces it to within 2 hours

- Inventory Accuracy Improvement: Increased from 97% to 99.9%+

- Employee Safety Enhancement: 90% reduction in high-risk operations

- Data Reporting Timeliness: Upgraded from weekly/monthly reports to hourly real-time updates

Implementation Challenges and Analysis

- RFID Tag Standardization Deployment: Tag quality and placement methods must remain uniform across different suppliers, items, and external environments to ensure optimal reading efficiency.

- Signal Interference and Shielding Issues: Metal items, liquids, and complex shelf structures can cause RFID signal attenuation, requiring scientific design of tag placement and optimization of reading parameters.

- Drone Navigation Safety and Battery Life: Due to complex warehouse spatial structures, the system needs efficient obstacle avoidance capabilities and intelligent path planning. Additionally, considering battery life limitations, batch operations must be reasonably planned.

- System Integration and Data Fusion: The warehouse ERP/WMS system must handle high-frequency mass data while ensuring network connectivity stability and intelligent analysis capabilities.

Implementation Strategies and Recommendations

- Phased Implementation, Pilot First: Prioritize pilot projects in warehouses with high-value goods and frequent inventory movement, then gradually expand to full coverage.

- Combine Selection with Customization: Customize RFID tag specifications based on specific logistics scenarios and cargo characteristics, while optimizing drone hardware configuration and software integration solutions.

- Strengthen Training and Process Reengineering: Systematically train staff to master intelligent equipment operation while optimizing inventory processes and establishing comprehensive exception handling mechanisms.

- Data Security and Privacy Protection: Enhance network security protection for inventory data, preventing data leaks and unauthorized operation risks.

The combination of drone and RFID inventory systems represents not only an upgrade in warehouse management technology but also a key breakthrough in pushing traditional logistics toward smart supply chains. With the integrated application of emerging technologies such as artificial intelligence, big data, and 5G, the innovative combination of drones and RFID will continue to empower intelligent logistics development, creating new competitive advantages for enterprises.

Walmart’s RFID Initiative and ARC Certification

As Walmart expands its RFID program from initial apparel categories to toys, home goods, electronics, beauty products, and more, RFID tag manufacturers are experiencing unprecedented transformation and development opportunities. This initiative not only further drives supply chain digital transformation but also reshapes the landscape of the tag manufacturing industry.

A Landmark Initiative in Retail Transformation

Walmart’s pioneering implementation of RFID has become a bellwether for the retail industry trend. Following suit, industry leaders like Nordstrom, BJ’s Wholesale Club, and Dick’s Sporting Goods have also successively made RFID tags a standard requirement for supply access, indicating that RFID application has become a non-negotiable “basic configuration” – non-compliant products will be excluded from mainstream retail channels.

What is ARC Certification? Why Should Manufacturers Pay Attention?

ARC Certification (Auburn University RFID Lab Certification) is an industry-authoritative standard provided by Auburn University’s RFID Laboratory. It establishes unified benchmarks for tag encoding accuracy, read range, durability, and overall performance in complex environments, ensuring RFID tags can be seamlessly and reliably read in large retail systems like Walmart.

Key Benefits of ARC Certification

- One-time Compliance Achievement: ARC testing rigorously covers core indicators including encoding, durability, adhesion, and complex material compatibility. Passing certification enables “one tag, multiple uses,” compatible with multiple retailers including Walmart and BJ’s.

- Multi-channel Compatibility and Scalability: Significantly reduces operational costs for manufacturers in dealing with different technical standards from multiple retailers, achieving standardized production and distribution.

- Sustained Performance Guarantee: ARC tags must prove their readability in demanding scenarios such as metal and liquid packaging, preventing logistics and sales data chain breaks.

- Market Access Tool: Suppliers using ARC-certified tags can greatly enhance partner confidence and avoid supply chain disruptions and additional losses due to tag issues.

High-Quality Tags: Key to RFID Project Implementation

As RFID expands to almost all product categories, tag manufacturers are moving from behind the scenes to the forefront, becoming indispensable technical partners in retail digital upgrade chains. Their role is no longer simply that of a “printer,” but rather to provide:

- Customized Solutions For different products like electronics, health items, and beauty products, RFID tags must be optimized based on product materials and packaging methods. For example, special interference-resistant designs for metal and liquid are key focus areas in ARC testing.

- Cross-domain Integration Capabilities Tag manufacturers must also collaborate deeply with system integrators and raw material suppliers to meet multi-dimensional RFID system requirements in supply chain traceability, automatic inventory, and retail analytics.

- Regulatory and Technical Foresight As global retail giants successively implement mandatory RFID tag requirements, companies with ARC tag development, production, and rapid iteration capabilities will become beneficiaries in the global supply chain upgrade trend.

The upgrade of Walmart’s RFID program has established new operational standards for the retail industry. ARC-certified RFID tags have become an insurmountable threshold for entering this new ecosystem.

Dual-Frequency Electronic Tag Technology: NFC and RAIN UHF

Dual-frequency electronic tags are smart labels that integrate two mainstream technologies:

- UHF component supports enterprise-level warehouse and logistics management, enabling long-distance, efficient bulk inventory and tracking.

- NFC component enables direct interaction between products and consumer smartphones, providing origin verification, customer service, and promotional activities through near-field applications.

Taking EM Microelectronic’s EM4423 chip as an example, these dual-frequency tags are widely used in retail, logistics, pharmaceuticals, healthcare, and fashion industries.

Technical Core—EM4423 Chip

Represented by EM Microelectronic’s EM4423, these tags feature highly integrated characteristics with the following main functions:

- Ultra-High Frequency (UHF) RFID: Compliant with EPC Gen2/ISO 18000-63 standards, enables long-range reading, particularly suitable for logistics, supply chain, and inventory management scenarios requiring rapid bulk scanning.

- High Frequency (HF) NFC: Compliant with ISO 14443-A standard, enables near-field reading and writing, fully compatible with smartphone NFC functionality, suitable for user interaction, authentication verification, and mobile payment assistance applications.

Beyond these core dual-interface functions, the EM4423 offers the following features:

- Storage Function: Built-in EEPROM storage area for product information, serial numbers, and usage records. Sufficient storage capacity meets diverse data storage requirements.

- Security Features: EM4423 employs multiple security protection mechanisms, including:

- Password Protection: Controls chip data read/write operations through access passwords.

- Access Rights Control: Enables independent access permissions for different storage areas.

- Unique Serial Number (TID): Each chip is equipped with a globally unique TID for identity verification and anti-counterfeiting traceability.

- Dual-Direction Data Bridge: Enables cross-interface data transmission, supporting data writing through one interface (like NFC) and reading through another (like UHF), with reverse operations also possible. This facilitates information transfer between different systems, such as writing product information via NFC phone and then conducting bulk inventory with UHF readers.

- Compatibility: Fully compliant with international RFID and NFC protocol standards, ensuring compatibility with various standard reading/writing devices.

- Passive Operation: EM4423 uses passive design, requiring no built-in battery, directly utilizing RF energy from readers for power and communication.

Typical Application Scenarios

1. Asset Management and Tracking:

- Industrial Equipment Tracking: By attaching EM4423 tags to equipment, tools, and components in factories or warehouses, automated inventory counting, location tracking, and usage record monitoring can be achieved, improving asset utilization, reducing losses, and simplifying maintenance procedures.

- High-Value Item Management: For jewelry, artwork, and electronic products, EM4423 provides secure authentication and anti-counterfeiting functions, facilitating origin tracing and transfer process tracking.

- Document and Archive Management: In libraries, archives, and offices, documents tagged with EM4423 enable quick searching, borrowing, and return management, significantly improving work efficiency.

2. Supply Chain and Logistics:

- Cargo Tracking: During transport, EM4423 tags on packaging can monitor location, status, and temperature (when equipped with sensors) in real-time, enhancing logistics transparency and security.

- Inventory Management: Warehouse RFID readers can quickly scan goods with EM4423 tags, automating receiving, shipping, and inventory counting, reducing human error and improving efficiency.

- Anti-counterfeiting and Traceability: In consumer goods, customers can verify product authenticity and access product information by scanning EM4423 tags with NFC phones.

3. Security and Access Control:

- Enterprise Access Systems: Employee cards equipped with EM4423 chips enable secure access control, record employee entry/exit information, and effectively manage unauthorized personnel.

- Parking Lot Management: Attaching EM4423 tags to vehicle windshields enables automatic vehicle identification and access management, improving parking lot operational efficiency and security.

- Event and Venue Access Control: Large events or venues can use tickets or wristbands with EM4423 chips for quick identity verification and entry management, reducing queue times.

4. Consumer Interaction:

- Smart Advertising and Promotions: Embedding EM4423 tags in posters, product packaging, or displays allows consumers to obtain coupons, product information, or participate in interactive activities via NFC phone scanning.

- Exhibition and Museum Guides: Exhibition or museum items equipped with EM4423 tags enable visitors to access text, image, or video introductions through NFC phone scanning.

- Smart Toys and Games: EM4423 can be applied in smart toys and games, enabling object recognition, data exchange, and interactive functions.

5. Other Innovative Applications:

- Medical Equipment and Supplies Management: Hospitals can use EM4423 to track medical equipment, medicines, and supplies, ensuring timely replenishment and use, enhancing medical safety.

- Pet Identification: Implanting EM4423 chips in pets enables identity verification and location tracking, facilitating the finding of lost pets.

- Waste Management: Smart waste bins can identify users through EM4423 and record waste disposal behavior, promoting waste sorting.

EM4423’s wide application across these fields is primarily due to its integrated features:

- Dual Interface: Supports NFC and HF RFID, facilitating interaction with smartphones and standard RFID readers.

- Security: Supports encryption and identity authentication, ensuring data security and anti-counterfeiting capabilities.

- Storage Capacity: Provides ample storage space for various types of information.

- Low Power Consumption: Suitable for various long-term operation scenarios.

In conclusion, EM4423, with its diverse application scenarios, excellent flexibility, and reliable security, has become an ideal solution for automation, traceability, and secure identification fields.