Higher Labor Costs, Higher RFID Adoption Rate?

The Engine of Transformation in a High-Cost Era: RFID’s Logic, Global Cases, and Industry Opportunities

— Your Next Operational Upgrade Revolution Starts Now with a Tiny RFID Tag

"People are the most expensive resource." This is a statement no business leader would disagree with.

Yet, what we are witnessing is a major trend: labor costs are continually rising worldwide, management is becoming increasingly complex, while enterprises demand ever-higher levels of process transparency, precise operations, and asset security. How can we break through these challenges and embrace a new, efficient, traceable, and automated way of working? The answer lies in a rapidly growing technology – RFID (Radio Frequency Identification).

Through this article, we aim to help global business owners, industrial managers, and innovation leaders truly understand why RFID has become the “new standard” in high labor-cost environments. Furthermore, we will share real-world digital transformation and efficiency leap cases from various industries and client sizes, and discuss how a specific RFID solution can genuinely optimize your cost structure and management benefits.

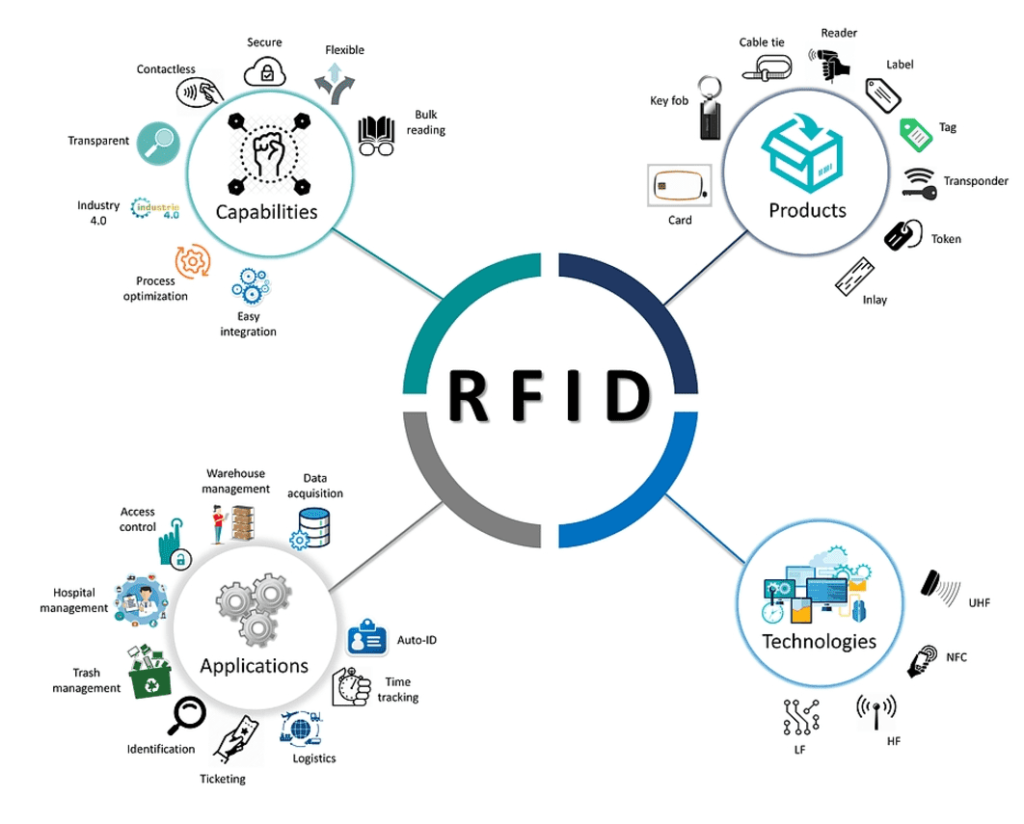

I. What is RFID? What Core Problem Does It Solve?

RFID (Radio Frequency Identification) is a technology that combines physical tags with wireless capabilities to enable rapid, batch-based identification and tracking of assets, goods, documents, and sample identities.

Compared to traditional barcode/QR code technologies, RFID offers unique advantages:

- Non-contact identification: No need for direct line of sight or precise aiming, greatly enhancing operational convenience.

- Batch reading capability: Simultaneously scan dozens or hundreds of items in seconds, increasing efficiency by hundreds of times.

- Large storage capacity: More attribute information can be stored directly on the tag, accommodating complex traceability needs.

- Encrypted and difficult to counterfeit: Effectively supports anti-counterfeiting and compliance management.

- Strong environmental adaptability: Remains stable even when attached to metal or glass surfaces, or in cold/hot/humid environments.

- Seamless integration with automation, IoT, and cloud platforms: Makes data truly “live” and business processes truly “fast.”

Why Have “Labor Costs” Become the Main Driver for RFID’s Commercial Adoption?

In any business analysis, labor input consistently occupies the most significant cost component. Manual operations, such as inventory counting, checkout, optimization, and reconciliation, force businesses to contend with high wages, high error rates, high turnover, and high management complexity. Therefore, using technology to replace or optimize manual labor can yield extremely significant returns on investment.

RFID precisely offers the “right medicine”:

- Reduces the number of personnel (e.g., self-checkout, automatic inventory, unmanned inbound/outbound scenarios);

- Minimizes human error (prevents mis-picking, mis-delivery, mis-matching, loss, or confusion);

- Significantly saves time (management, searching, and inventory processes completed in seconds);

- Opens the door for automation and digital transformation (full process traceability, intelligent collaboration, and process re-engineering).

You’ll find that the higher the labor cost in a market/industry, the more apparent the economic benefits of RFID become, leading to faster adoption rates. This is the fundamental logic behind the accelerated RFID adoption in developed countries like Europe, the US, and Japan in recent years.

II. Global Case Studies: Industry Transformation Examples in a High Labor Cost Era

- The RFID Boom in High-Labor-Cost Regions like Europe, the US, and Japan

Retail Transformation: Self-Checkout, Accurate Inventory, Employee Empowerment

Taking high-end fashion retail in Europe as an example, more and more stores have adopted RFID self-checkout and inventory systems in recent years. For instance, a large department store in Munich, Germany, after deployment, reduced inventory time from two full days to just one hour, achieving 99.9% accuracy. Employees shifted from manual handling to customer service, and customer checkout lines significantly shortened. This, undoubtedly, is compelling proof of cost reduction and efficiency improvement.

Warehousing & Logistics: Automated Inbound/Outbound, Significant “Manpower Liberation”

Leading US and Japanese logistics companies have achieved exponential increases in per-person handled business volume through full-process RFID tracking (including picking, loading, cargo tracking, transfers, and all other nodes). What used to require dozens of employees for a large warehouse’s monthly inventory can now be completed by two people with RFID readers in one night. Logistics anomalies are immediately identifiable, and cargo damage is greatly reduced.

Manufacturing: Material Flow, Production Traceability, Error Prevention

Automotive giants like Honda and Toyota in the US have implemented RFID for material “gate-in/gate-out” and electronic inventory Kanban systems. This has drastically reduced manual losses related to production preparation, material staging, and mis-deliveries. They also ensure full lifecycle traceability and anti-counterfeiting for finished vehicles and spare parts.

- The “Exceptional Nation”: Why Are Low-Labor-Cost Markets Also Eager for RFID?

Take India as an example. It’s often referred to as “the new factory of the world,” seemingly with cheap labor. So why has RFID deployment grown so astonishingly in recent years?

The answer reveals the multifaceted value of RFID – it’s not just about saving money, but also about bringing significant breakthroughs in management, service, and compliance.

- Healthcare Scenarios (Apollo Diagnostics, Hospitals/Labs, Pharmaceutical Transport)

In healthcare, with numerous steps in sample flow, testing, and handover, the margin for error is extremely low. Traditional manual record-keeping can easily lead to omissions or confusion, directly impacting patient safety. RFID tags ensure an electronic trail for every step, and automatic alerts for management have become an industry standard. - Express Logistics Industry

Global logistics giant DHL deployed RFID parcel tracking systems in India, enabling real-time transport monitoring, loss prevention, and efficiency management. Even during the pandemic, “contactless” delivery remained highly efficient, significantly boosting customer satisfaction. - Industrial / Smart Manufacturing

Automotive OEMs like Honda and Hyundai have invested in RFID monitoring for their production lines, achieving refined manufacturing management, optimizing supply chain collaboration, and shortening new project launch cycles, while reducing significant unnecessary manual waste. - Smart Hardware and Warehouse Robotics

Companies like TCI have integrated RFID into robots and AGVs (Automated Guided Vehicles), achieving “end-to-end automation” in warehousing, which has dramatically improved storage and retrieval efficiency.

In summary: When business processes are complex, and there’s a high demand for precision and security, RFID becomes essential automation infrastructure – it doesn’t just “save labor,” it strengthens a company’s core competitiveness.

III. A "Problem-Solving Tool" for Lab Digital Transformation: The Innovative Gnosko RFID Case

High-end laboratories, biobanks, medical sample repositories, forensic institutions, and CROs are highly sensitive to management efficiency and compliance reliability, yet they also face budget constraints. Gnosko’s solution perfectly embodies the concept of “high value, low barrier.”

- A comprehensive RFID-integrated Chain of Custody (CoC) platform with complete features like real-time traceability, automatic inventory, cold chain monitoring, and compliance alerts, supporting international standards such as ISO 17025, GMP, GxP.

- Product Innovation: Plug-and-play, deployable in days, eliminating lengthy integration periods.

- Business Innovation: Bundled with lab consumables, transforming capital expenditure into operational expenditure, making it almost “zero-barrier” to experience automated management.

After implementing the Gnosko RFID platform, customers reported tangible benefits including “80% reduction in freezer audit time,” “100% sample traceability compliance across multiple sites,” and “immediate alerts for operational errors,” comprehensively enhancing laboratory process security and operational efficiency.

Insight: RFID adoption is not solely driven by spontaneous cost considerations; it can also be accelerated by innovative business models that break through financial barriers, fostering digital transformation.

IV. What Has RFID Truly Changed? A "Visible Future" for Businesses

- Revolutionizing Inventory and Traceability

- Past: Manual scanning of each item, low efficiency, high error rates, reliant on experience.

- Present: A pallet of goods, a freezer of samples, a row of files – scanned in seconds with an RFID reader, with alerts for missing items and real-time online verification.

- From Manual to Collaborative, From Obscure to Transparent

- Operators are no longer performing repetitive barcode scanning; instead, they coordinate inspections and perform intelligent analysis. Managers see real-time status across the entire process, making optimized decisions as needed.

- Scalability: Breaking Down Data Silos, Driving Industrial Upgrades

- Data collected by RFID can be seamlessly integrated with ERP, cold chain logistics, unmanned warehouses, sorting robots, and any other business system, empowering full-link information transparency and intelligence.

- Enhanced Security, Improved Compliance

- Anti-counterfeiting, access control, theft prevention, tamper detection… Every asset/sample/product has a unique ID and log, making errors, theft, or mis-transfers immediately traceable and accountable.

Going further: Empowered by digital technologies like AI, IoT, Big Data, and Blockchain, RFID’s value will continuously upgrade, from automatic data collection to automated decision-making, predictive alerts, reaching new heights in enterprise management capabilities.

V. Is RFID Still Expensive? What's Happening Globally?

The old perception: RFID hardware and systems are expensive, only big corporations can afford them.

- The world is changing! Over the past decade, the manufacturing cost of RFID tags has continuously decreased.

- The industry is getting “hyper-competitive” – from antennas and chips to integrated packaging, major global manufacturers are in fierce competition, driving down the unit cost of RFID tags and equipment. The unit cost of RFID is now far lower than the cost of most manual operations.

- Mainstream RFID system providers are also increasingly offering “pay-per-use,” “lightweight SaaS,” and “localized simple deployment” models, making RFID an affordable infrastructure for companies of all sizes, across all processes, and throughout various industries.

Who, or what kind of company, should consider RFID first?

- Those with high unit labor costs, or who need to allocate manpower across multiple locations.

- Those whose inventory/auditing/sample handover processes are cumbersome, time-consuming, and error-prone.

- Those who are highly sensitive to loss, damage, or counterfeiting.

- Those who are driven by compliance and regulatory requirements for precise and transparent processes.

- Those whose business volume, product/sample/asset categories are extremely diverse, making manual management virtually impossible.

For these groups, an RFID investment often pays for itself within months and brings long-term benefits to the enterprise.

VI. Your Next Step: Embark on Your RFID Smart Upgrade Journey

RFID is not an “unreachable luxury”; it is becoming the “new utility” for efficiency across all industries!

Our Commitment:

As a leading global provider of RFID tags and comprehensive solutions, MAKA RFID not only possesses world-class craftsmanship and cost-effectiveness but also boasts extensive experience serving clients across various industries and scales. We can customize end-to-end tag and system integration solutions for you, whether your business is in Europe, America, Asia, Latin America, or Africa; whether you are in apparel, logistics, healthcare, laboratories, or smart manufacturing; whether your demand is in the millions or you are just starting a pilot project – we will listen to your specific needs and design the most suitable and cost-effective solution path.

Connect with us now for a complimentary RFID efficiency assessment!

Are you currently facing any of these challenges?

- High costs that are hard to reduce, with no clear breakthrough.

- Increasing business complexity, with existing manual labor and systems struggling to cope.

- Growing demands from regulators/customers for transparency and traceability.

- A desire to be at the forefront of digital and smart transformation, gaining a market edge.

The solution to all of these can begin with a discussion about our RFID products and solutions.

The tide of digitalization is surging. RFID is not a one-time IT overhaul – it’s your starting point for overcoming management bottlenecks, unleashing human potential, and achieving new business gains.

Stop letting labor and management costs slow you down. Turn high “redundancy” into visible profits, and transform “uncertainty” in your processes into “peace of mind” for every transaction.

RFID is becoming a global consensus for businesses. The transformation is within your choice.

We are here, awaiting your inquiry.

High-efficiency upgrades across all industries begin with RFID. We look forward to creating the future with you!

info@makarfid.com