Walmart's RFID expansion stimulate the retail industry?

In 2022, Walmart made a major announcement that caused a stir in the RFID industry.

As a world-leading retailer, Walmart revealed its ambitious plan to expand the application of RFID technology to other key retail sectors beyond clothing.

Walmart required its suppliers to implement RFID tagging for home goods, sporting goods, electronics, and toys by September 2, 2022. This strategic move highlighted Walmart’s confidence in the effectiveness of RFID technology and its potential to completely transform inventory management in different retail industries.

Now, nearly a year after the RFID mandate, the question arises: has it truly stimulated the application of RFID in the retail industry beyond apparel and footwear?

It is well known that the retail RFID market has tremendous growth potential in recent years, with UHF RFID technology being essential. According to IDTechEx data, over 72% of UHF RFID tags were deployed in the apparel and footwear sector last year.

This dominance in the field of retail clothing and footwear tags not only holds the largest market share in terms of tag quantity but also holds significant market value in the ultra-high frequency (UHF) field. IDTechEx predicts that this trend will continue over the next decade, considering that retailers have been deploying RFID technology with highly standardized and rapidly implemented UHF RFID solutions, and the return on investment in these industries has been proven.

While apparel and footwear continue to lead the UHF RFID market, other retail sectors are also experiencing significant growth. Particularly, participants in Walmart’s supply chain have seen double-digit growth due to Walmart’s RFID mandate. This positive market response aligns well with IDTechEx’s predictions regarding the adoption of UHF RFID technology in other retail industries.

IDTechEx emphasizes the evolving prospects, stating that the growth in these sectors has exceeded previous expectations. The success of Walmart’s mandate has played a crucial role in stimulating usage and promoting demand growth. Retailers across various industries have recognized the benefits of UHF RFID technology and are utilizing it to enhance their operational efficiency.

Although there is a growing momentum in adopting item-level tagging (one tag per item) in other retail sectors, there are still significant challenges to overcome in large-scale implementation.

One of the main obstacles is the cost of labeling each item, which may be prohibitive for some retailers. Secondly, the increased use of RFID tags without proper recycling measures may lead to electronic waste, raising sustainability concerns. Thirdly, there are technical and implementation challenges, particularly when dealing with items containing liquids or metals. Lastly, the ecosystem for large-scale RFID implementation in other retail sectors (beyond apparel and footwear) is not yet fully mature, adding complexity to the adoption process.

These issues highlight the necessity for continuous innovation and collaborative efforts within the RFID industry to address cost, sustainability, and technological limitations, and to promote the development of a robust and efficient ecosystem that ultimately supports widespread implementation in the retail industry.

RFID has gradually gained market recognition, and it is believed that more companies will join the wave of RFID adoption.c

Application of RAIN RFID in the Retail Industry: Driving Transformation for Retailers

Brands using RAIN RFID for inventory management report:

- 25-30% improvement in inventory accuracy

- Up to 50% reduction in out-of-stock situations

- Up to 80% increase in shipping and picking accuracy

- 25x faster cycle counting time

These advantages give retailers more time and energy to focus on delivering the best customer experience and ultimately generate a significant return on investment.

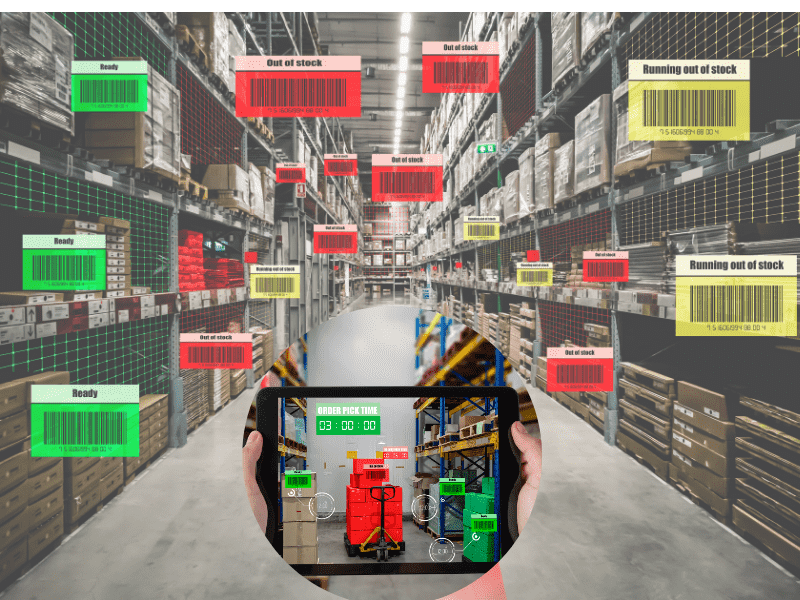

With RFID, retailers can increase single-item inventory accuracy from 65% to 99%. With accurate inventory information, retailers can eliminate stockouts, sell products at full price until the last item, fulfill store product orders, and ensure timely replenishment of sales floor inventory. This level of visibility also instills confidence in retailers that their products are where they should be. Accurate, real-time knowledge of available inventory and replenishment stock locations (store, backroom, warehouse, or distribution center) enables omnichannel fulfillment options such as “buy online, pickup in-store.”c

For example, at Nike, products receive RAIN RFID tags during manufacturing and are tracked from the factory to the warehouse and then to stores. “RFID gives us the most comprehensive view of inventory we’ve ever had,” said Mark Parker, Nike’s Chairman and former CEO. “It’s rapidly becoming our most precise tool in the arsenal to meet the specific needs of individual consumers at the right time.”

Walmart, an early enthusiast of barcodes, shifted its focus to RFID as a way to improve inventory management. After a brief trial of the technology in the early 2000s, the company started requiring apparel suppliers to implement RFID by 2020. As of September 2022, all toy, home goods, electronic, and sporting goods packaging must also be tagged. According to Dunne, since Walmart’s initial RFID trials, costs have “significantly” decreased as adoption rates across the industry have increased.

FAQ: Walmart RFID Mandate

Introductory Questions

Since beginning to implement RFID technology in 2020, Walmart has seen dramatic results. Improved on-hand accuracy has led to increased online order fulfillment and customer satisfaction. RFID will help improve inventory accuracy across our assortment, resulting in a better in-store shopping experience for customers, enhanced online and pick-up in-store capabilities, and greater sales opportunities.

- Improved inventory accuracy: RFID tags can be read from a distance, which means that Walmart can quickly and easily track the location of its inventory. This has led to a significant improvement in inventory accuracy, which has saved the company money.

- Reduced theft: RFID tags can also be used to deter theft. When items are tagged with RFID, they can be easily tracked, which makes it more difficult for thieves to steal them.

- Improved customer service: RFID data can be used to provide customers with real-time information about product availability. This can help customers find the products they are looking for quickly and easily.

- Improved replenishment: RFID data can be used to identify which products are low in stock and need to be replenished. This helps Walmart to ensure that its shelves are always stocked with the products that customers want.

- Improved pricing: RFID data can be used to track the price of products throughout the supply chain. This helps Walmart to ensure that its prices are competitive and accurate.

- Improved compliance: RFID data can be used to track product recalls and other compliance issues. This helps Walmart to ensure that it is in compliance with all applicable laws and regulations.

No, all RFID expansion suppliers for the specified departments will need to include RFID tags on all product /packaging. Suppliers failing to tag will impact the implementation timing in stores.

Walmart recently completed RFID mandates for Appareland Car Tires. The following departments should currently be arriving in store with RFID tags:

Home Departments: D14,D17, D20,D71,D74,

Electronics Departments: D72, D87

Toys Department: D07

Sporting Goods Departments:D09

Automotive Departments: D10

New Departments Where Any Items That Arrive in Store on or before February 1, 2024 Should be Tagged:

Home Departments: D19

Entertainment Departments: D05, D06,D21

Hardlines Departments: D03, D10, D11, D12, D16

Introducing RFID tagging should be relatively simple. The only difference between RFID tags and normal tags is the embedded inlay and EPC (vs. UPC). Suppliers must attach RFID tags to product packaging and ensure the accuracy and readability of the tags.

Suppliers can visit Walmart’s official website or contact Walmart’s customer service department to obtain Walmart RFID Mandate. Walmart’s provides an introduction, standards, and guidelines on RFID technology, where suppliers can find specific steps and requirements on how to comply with Walmart’s RFID requirements.

Basics of RFID

RFID stands for Radio Frequency Identification. RFID tags include an RFID inlay that has an antenna for communicating and an integrated circuit for storing data. RFID tags can be

read quickly with a scanner that can scan multiple products at the same time. A key feature

of RFID tags is serialized identification that uniquely identifies every individual product.

An RFID system consists of a scanning antenna, a transceiver, and a transponder. These components work together to form an RFID reader. There are two types of RFID readers: fixed and moving. The reader can be network-connected and either portable or permanently attached. It uses radio waves to send signals to activate the tag. Once the tag is activated, it sends data back to the antenna. The transponder is located inside the RFID tag and can be read. The read range of RFID tags varies depending on factors such as tag type, reader type, RFID frequency, and interference. Tags with higher power have a longer read range.

The term “Electronic Product Code” (EPC) refers to the GS1 standards-compliant data encoded in the RFID tag.

- The EPC logo is the printed indicator that an RFID tag (specifically, a UHF frequency band tag) with GS1 standards-based encoding is present.

Questions on tagging, sticker and secondary hangtag

Walmart will NOT provide RFID tags. Suppliers should source RFID tickets through an RFID tag provider directly.

- Product be tagged or labeled with an passive RFID chip of the appropriate specification. This can be either:

- A product tag or label with printed retail information and embedded with an RFID chip;

- A sticker with an embedded RFID chip that is then applied to another tag or label with the printed retail information;

- Two separate tags or labels, affixed to the product together: one with an embedded RFID chip and the other with printed retail information

- The RFID chip must be encoded with an Electronic Product Code (EPC). The EPC must be SGTIN-96 formatted, in accordance with the GS1 Tag Data Standards

- The tag, label, or sticker that contains the RFID chip must be visually distinguished with a printed EPC Logo

The RFID-enabled ticket must be affixed to the product in accordance with the GS1 Apparel and General Merchandise Placement Standards

RFID Inlays: Auburn RFID Lab approval is mandatory.

Your solution provider will need to know what the valid UPC/EAN barcode values are for your products. A valid UPC/EAN barcode is based on a licensed GS1 Company Prefix. This enables the Solution Provider to determine the GTIN-14 value, which is part of the EPC.

There is a slightly higher cost to RFID inlay tickets. The amount can vary based on suppliers and options. We are confident that the investment will pay off for each supplier in terms of increased accuracy driving higher regular price sales.

Can use either Primary or Secondary labeling. Primary would involve a RFID tag or a sticker on your existing tag. Secondary would involve a RFID tag or sticker that you add on an additional tag.

It is not requiring RFID information be tied to ASNs. RFIDs are only currently required for products

- Identify the Dept and Subcategory for the product (100+)

- For example: D7- Toys, Pool/Beach Toys

- Can be found in Walmart’s RFID Playbook

- Contact your RFID Supplies Account Representative for a Quote

- RFID supplier provided Certified Inlays that meet ARC Specs W1, W3, W4, Y

- The labels and inlays to meet Walmart timeline and specifications

- Submit printed and encoded product ARC RFID Lab for approval

- Start RFID tagging

Auburn University’s RFID Lab (ARC) acts as an independent third party that helps businesses create and test relevant testing specifications. RFID Inlay suppliers send new inlays to ARC to test against these specifications. Walmart is using different ARC specifications depending on the Category and Subcategory of products to ensure they get the performance expected in their application.

- Select an ARC approved Inlay

- Follow proper Tag Placement

- Follow Playbook for Print and Encoding