Implantable Medical Mini RFID Tags

The tags are designed and tested to strict medical-grade standards, ensuring stable and reliable operation even in extreme medical environments. They feature ultra-miniaturized design, excellent biocompatibility and safety, can withstand multiple high-temperature high-pressure steam sterilization cycles, and provide outstanding read performance.

This miniature, highly reliable innovative product is designed to address every critical aspect from instrument management and sample tracing to patient safety, helping medical institutions move toward a smarter, more efficient, and safer future. Our implantable medical mini RFID tags are ultra-miniature wireless identification devices specifically designed for stringent medical environments. They can be safely implanted in medical devices, inside packaging, and even used for biological identification in specific research scenarios. We use top-tier biocompatible materials and cutting-edge manufacturing processes to ensure each tag is not only microscopically small and nearly imperceptible, but also possesses exceptional durability and long-term stability, performing excellently even under repeated sterilization, extreme temperatures, and complex bodily fluid environments.

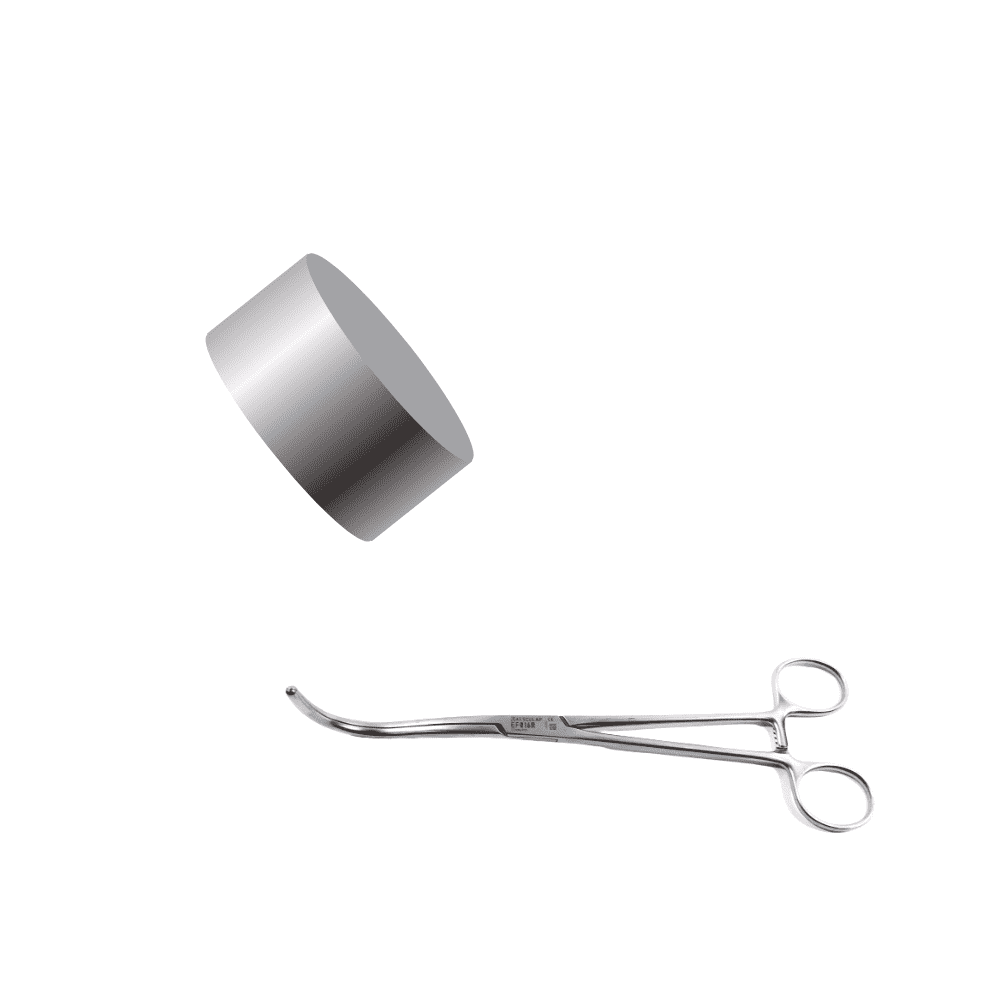

- Ultimate Miniaturization Design Size breakthrough: Diameter less than Ø2mm, easily integrated into various small medical devices. Flexible applications: Suitable for catheters, endoscopes, implants (such as orthopedic implants, pacemaker casings), sensors, disposable medical consumables, and various high-precision medical products.

- Outstanding Compatibility and Safety Medical-grade encapsulation: Packaged using environmentally friendly materials. Long-term stability: Long-term reading distance around 1m, still reaching 70cm after high-temperature and high-pressure steam sterilization cycles. Comfortable use: When embedded in instruments, protrusion range is only 1mm, causing no discomfort during use and not affecting operation.

- Unparalleled Tolerance and Reliability Resistant to extreme environments: Designed to withstand the most stringent challenges in the medical industry. Resistant to high-temperature and high-pressure sterilization: Independently tested to withstand up to 650 cycles of medical-grade high-temperature and high-pressure steam sterilization (such as autoclave sterilization), ensuring the safety and traceability of reusable instruments. Chemical corrosion resistance: Resists corrosion from common medical disinfectants, cleaning agents, and body fluids. High shock resistance: Solid structure resists physical impact, ensuring functionality remains intact in complex operating environments.

- Powerful Traceability and Data Management Unique identity: Provides a unique digital identity for each medical device, sample, or individual, traceable from production source to final use. Automated data collection: Achieves fast, precise data collection through contactless RFID reading technology, greatly improving efficiency and reducing manual errors. Information integration: Can seamlessly integrate with hospital information systems (HIS), laboratory information systems (LIS), instrument management systems, etc., building a smart healthcare ecosystem.

- Customized Services We deeply understand the unique needs of different medical applications. In addition to standard products, we also provide:

Specifications

Dimensions (mm) |

Ø2mm |

Material |

Bio-friendly environmentally friendly materials |

Frequency |

UHF(US/FCC) UHF(EU/ETSI) |

Operating Temperature(°C) |

-40 to 200 |

Storage Temperature(°C) |

-40 to 85 |

IP Rating |

IP68 |

Applicable Surface |

On-metal |

RFID Chip |

NXP, Impinj, Alien |

RF Interface Protocol |

EPC Class1 Gen2 ISO/ISO18000-6C |

Color |

black / Customized |

Reading Distance |

1 meter |

Application |

Metal assets tracking IT assets management Surgical instrument management Future innovative medical care |

For additional details or to request a quote, please contact us. Join us at MAKA RFID and redefine your RFID experience.